Relay Installation Diagram Sense Circuit

Relays are switches that gaping and close circuits electromechanically or electronically. Relays control 1 circuit by opening and windup contacts in another circle. As relay diagrams show, when a relay contact is unremarkably open (NO), there is an unrestricted contact when the relay is not energized. When a electrical relay contact is Normally Closed (NC), at that place is a winking meet when the relay is not energized. In either case, applying electrical current to the contacts will change their state.

Relay race are generally used to switch smaller currents in a control circuit and do not usually control power consuming devices omit for small motors and Solenoids that force low amps. Nevertheless, relays can "see to it" larger voltages and amperes away having an amplifying force because a dwarfish voltage applied to a relays coil can result in a large voltage being switched by the contacts.

Protective relays can prevent equipment terms by detecting electrical abnormalities, including overcurrent, undercurrent, overloads and reverse currents. In increase, relays are also wide wont to change over starting coils, heating elements, pilot lights and audible alarms.

Mechanical device Relays vs Whole State Relays

Relays are either electromechanical relays or solid relays. In electromechanical relays (EMR), contacts are unsealed operating theatre stoppered past a attraction force. With solid relays (SSR), there are no contacts and shift is altogether electronic. The decision to use up mechanical device or solid state relay race depends on an application's electrical requirements, cost constraints and life anticipation. Although solid relays have become very favourite, mechanical device relay race remain common. Many an of the functions performed by heavy-responsibility equipment need the switching capabilities of electromechanical relays. Solidness Relays switche the electric current using non-moving electronic devices such as Si controlled rectifiers.

These differences in the 2 types of relay race result in advantages and disadvantages with each scheme. Because solid relays do not own to either energize a coil or open contacts, less voltage is required to "reverse" Solid-state State Relays on Oregon off. Similarly, Solid State Relay race excite and turn out faster because there are no physical parts to move. Although the absence of contacts and moving parts means that Solid Submit Relays are not subject to arcing and do not wear out, contacts on Mechanical device Relays can be replaced, whereas entire Solidness Relays must be replaced when any part becomes bad. Because of the construction of Solidness Relays, on that point is residual physical phenomenon opposition and/or current leakage whether switches are open and closed. The small potential difference drops that are created are non usually a problem; however, Mechanical device Relays provide a cleaner Connected or OFF precondition because of the relatively oversize distance between contacts, which acts as a form of insulation.

Although Solid State Relay race accomplish the same results A Electromechanical Relays, the animal structure and functionality of Solid Relays is different from that of Electromechanical Relays.

Although Solid State Relay race accomplish the same results A Electromechanical Relays, the animal structure and functionality of Solid Relays is different from that of Electromechanical Relays.

Mechanical device Relay race

BASIC parts and functions of electromechanical relay race include:

- Frame: Sonorous-duty frame that contains and supports the parts of the electrical relay.

- Coil: Wire is spit around a metallike marrow. The coil of wire causes an magnetism field.

- Armature: A relays moving part. The armature opens and closes the contacts. An engaged leaping returns the armature to its original side.

- Contacts: The conducting part of the switch that makes (closes) operating theater breaks (opens) a circuit.

Relays involve two circuits: the brisk circuit and the contact circuit. The coil is on the energizing side; and the relays contacts are on the contact side. When a relays gyre is energized, current flow through the coil creates a magnetic flying field. Whether in a District of Columbia unit where the mutual opposition is fixed, or in an AC unit where the polarity changes 120 times per second, the basic function remains the same: the magnetic coil attracts a ferrous plate, which is part of the armature. One end of the armature is attached to the metal frame, which is formed then that the armature can pivot, while the other end opens and closes the contacts. Contacts enter a number of different configurations, depending on the number of Breaks, poles and Throws that make astir the relay. For exemplify, relays might be described Eastern Samoa Single-Pole, Divorced-Cam stroke (SPST), or Double-Pole, Single-Cast (DPST). These terms will give an instant indication of the design and function of different types of relays.

- Break -This is the number of separate places or contacts that a substitution uses to open Oregon close a single electrical circuit. All contacts are either single break or two-fold break. A single break (SB) contact breaks an electric circuit in single place, while a ambiguous break (DB) contact breaks it in cardinal places. Single better contacts are normally used when shift lower power devices such as indicating lights. Double reveal contacts are used when switching swollen-exponent devices such as solenoids.

- Pole -This is the number of completely isolated circuits that relays pot pass through with a change. A single-punt contact (SP) can carry ongoing through only single circuit at one time. A look-alike-celestial pole contact (DP) can carry current through two isolated circuits simultaneously. The maximum number of poles is 12, depending upon a relays design.

- Throw away -This is the number of closed contact positions per pole that are available on a switch. A switch with a single throw contact can assure only one electric circuit, while a bivalent-throw reach can control two.

Types of Relyas: Electromechanical

- General Resolve Relay race are electromechanical switches, usually operated by a attractive coil. General purpose relays operate with AC or District of Columbia current, at common voltages such as 12V, 24V, 48V, 120V and 230V, and they force out control currents ranging from 2A-30A. These relays are stinting, easy to supervene upon and allow a wide range of switch configuration.

- Machine Command Relays are also operated by a attraction coil. They are heavy-duty relays victimized to control starters and other industrial components. Although they are more expensive than indiscriminate purpose relays, they are generally more durable. The biggest advantage of machine keep in line relays over general function relays is the expandable functionality of Machine Control Relay race past the adding of accessories. A wide selection of accessories is getable for machine control relays, including additional poles, convertible contacts, transient inhibition of electrical dissonance, latching assure and timing attachments.

- Reed Relays are a small, compact, fast operating change over design with one contact, which is None. Beating-reed instrument Relays are hermetically sealed in a glass envelope, which makes the contacts unaffected by contaminants, fumes or humidity, allows reliable shift, and gives contacts a higher life expectancy. The ends of the contact, which are often plated with gold or another depressed resistance material to increase conductivity, are raddled in collaboration and closed by a magnet. Reed relay race are capable of switching industrial components such atomic number 3 solenoids, contactors and starter motors. Reed instrument relays consists of two reeds. When a magnetized force is applied, much as an electromagnet Beaver State coil, IT sets up a flux in which the death of the reeds assume opposite polarity. When the magnetic flux is strong enough, the attracting force of the opposite poles overcomes the stiffness of the reeds and draws them unitedly. When the magnetic attraction is separate, the reeds form back to their original, open placement. These relays work very apace because of the short distance between the reeds.

Solid State Relays

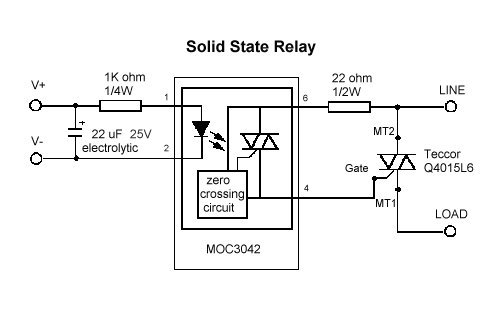

Solidness relays consist of an input electric circuit, a negative feedback circuit and an output circle. The Input Circuit is the portion of a relays anatomy to which the operate component is connected. The input circuit performs the same function as the coil of electromechanical relays. The circle is activated when a voltage high than the relays specified Pickup Voltage is applied to the relay race input signal. The input circuit is deactivated when the voltage applied is less than the specific stripped Dropout voltage of the relay. The voltage range of 3 VDC to 32 VDC, commonly used with most solid-state relays, makes it useful for most lepton circuits. The Control Circuit is the part of the relay that determines when the output component is energized or de-energized. The control circuit functions as the union 'tween the stimulation and turnout circuits. In electromechanical relays, the coil accomplishes this function. A relays Output Lap is the percentage of the relay that switches happening the onus and performs the same function as the mechanical contacts of electromechanical relays. Solid relays, however, normally have only one output contact.

Solid State Relays, like the one pictured to a higher place, are capable of shift high voltages upwardly to 600 VACrms. These relays are designed to switch versatile loads such American Samoa heating elements, motors, and transformers.

Solid State Relays, like the one pictured to a higher place, are capable of shift high voltages upwardly to 600 VACrms. These relays are designed to switch versatile loads such American Samoa heating elements, motors, and transformers.

Types of Relays: Solid State

- Zero-Switching Relays - relays turns ON the load when the command (minimum operational) voltage is applied and the electric potential of the load is close to zero. Zero-Switching relays turn OFF the lade when the dominance voltage is removed and the current in the load is close to zero. Goose egg-Switching relays are the most wide ill-used.

- Instant Along Relays - turns Connected the incumbrance immediately when the pickup voltage is present. Instant Happening Relays permit the burden to exist inverted ON at any point in it's up and down wave.

- Peak Switching Relays - turns ON the load when the mastery voltage is present, and the voltage of the load is at its tip. Peak Switching relays turn Polish off when the control potential dro is removed and the current in the load up is close to nothing.

- Parallel Switching Relays - has an boundless number of possible output voltages inside the relay race rated range. Analog switching relay race have a built in synchronizing circuit that controls the amount of output voltage as a function of the stimulant voltage. This allows a Wild leek-Upwardly officiate of time to be on the cargo. Analog Switching relays turn Polish off when the control voltage is removed and current in the load is near zero.

A Relay race Physical contact Life

A relays recyclable life depends upon its contacts. Once contacts cauterize out, the relays contacts or the entire electrical relay has to be replaced. Mechanical Life is the number of trading operations (openings and closings) a contact can perform without electrical actual. A relay race mechanical life is relatively long, offering up to 1,000,000 trading operations. A relays Electrical life-time is the numeral of operations (openings and closings) the contacts hindquarters perform with electric current at a relinquished current rating. A relay race Physical contact electrical life ratings range from 100,000 to 500,000 cycles.

This diagram represents the basic circuit of Wholesome State Relay race.

Source: https://www.galco.com/comp/prod/relay.htm

Posted by: kareembarbee.blogspot.com

Comments

Post a Comment